Large CNC Machines

When you need to produce large-scale, complex parts with extreme precision and efficiency, you need an advanced large CNC machine that’s up to the task. As a premier distributor of top-tier heavy machining solutions for over 20 years, United Precision Services provides North American manufacturers with the most reliable large volume CNC mills, lathes and other manufacturing machinery. We represent industry-leading global brands known for their expertise in large-part machining.

Our selection of gantry mills, 5-axis portals, vertical turning centers and more give you the power and accuracy to machine parts up to 6 meters high while minimizing set-up times. With our value-added services like specialized foundation design and responsive nationwide support teams, we’ll help maximize your large CNC performance.

Unmatched Performance and Versatility of Large CNC Machines

From precision-engineered components to large fabrications, large volume CNC machines are redefining the standards of machining performance. These machines, designed with high rigidity and power, provide an unrivaled combination of speed, accuracy and flexibility in various applications. Built to handle large workpieces, their robust construction and advanced technologies, such as the automatic tool changer and automatic pallet changers, further enhance their efficiency and productivity.

Large CNC machines are highly customizable, with options for spindle extension, OEM retrofit or changing the end mill. In addition, they offer various accessories such as the universal head, angle head and more, enhancing their versatility and adaptability to differing machining requirements.

Additionally, large CNC machines come with several mechanisms that ensure precision in operations. For instance, the rotation and movement of the machine are controlled by a ball-end mill system for accurate machining tasks.

Accompanied by an effective cooling system, it ensures smooth operation even under harsh and demanding conditions. They also have different types of tool changers that ensure the correct engagement and disengagement of the end mills, enhancing their precision and performance.

Our CNC Machines

Universal Mills

Universal mills are our go-to solution for large fabrications. These machines offer high rigidity and accuracy due to the presence of a robust spindle unit. They are characterized by wide slideways and ball screws, which provide stability during operation.

Capable of a high spindle speed and equipped with an angle head, these mills are suitable for complex tasks. The spindle extension function enables them to reach places that are not easily accessible.

Horizontal Lathes

Our horizontal lathes, designed for turning large workpieces, perform impressively due to their high stock removal rate. The spindle motor of high rigidity provides a reliable power source, ensuring smoother operations.

Enhancements like a universal head and temperature sensor optimize the machine’s performance. Moreover, an automatic pallet changer facilitates quick workpiece placement and removal, ensuring efficient operations.

Vertical Lathes

Vertical turning lathes stand apart in the performance of operations like hard turning and grinding. They provide a stable base for large workpieces, thanks to the cast iron body and large spindle diameter. A cross rail provides added support to the workpiece during operations.

Key features like ball end mills, vertical machining centers and automatic pallet changers facilitate versatility and productivity. Equipped with precision-positioning equipment, vertical lathes excel at handling intricate tasks.

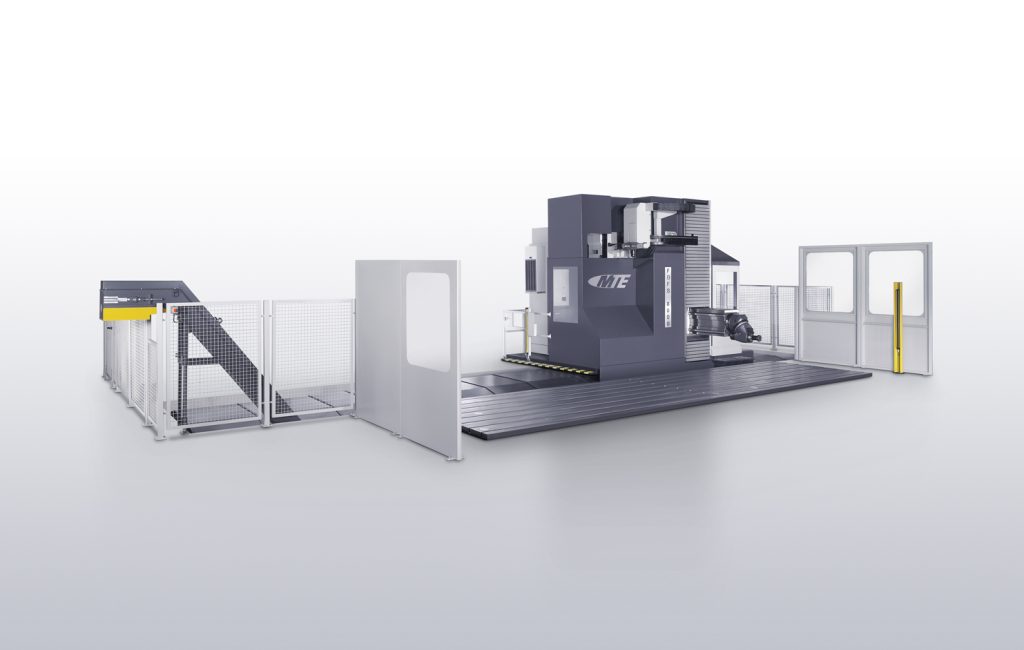

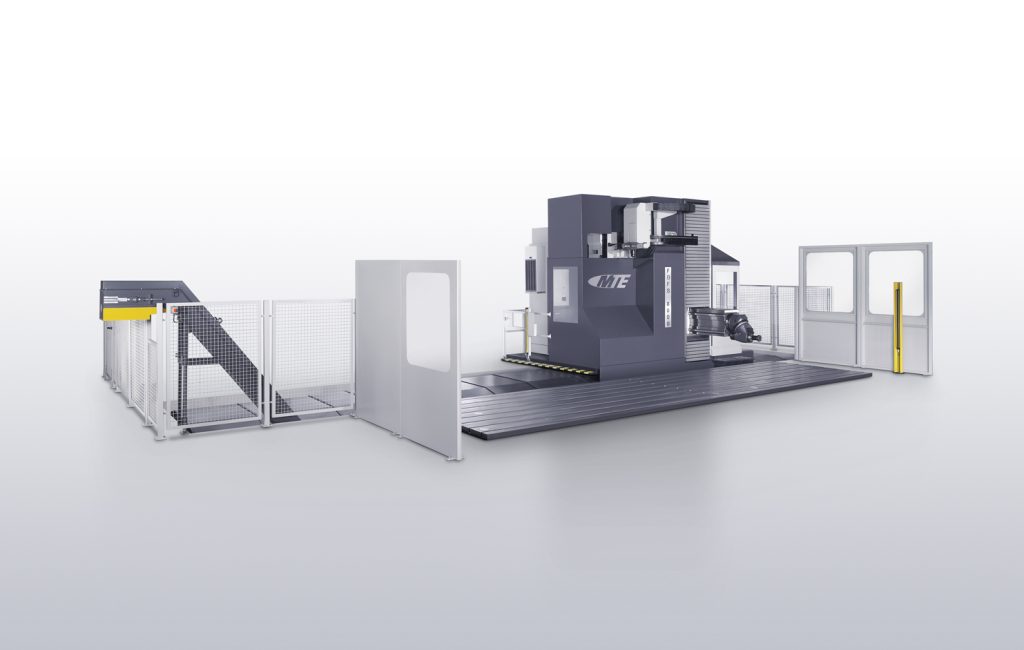

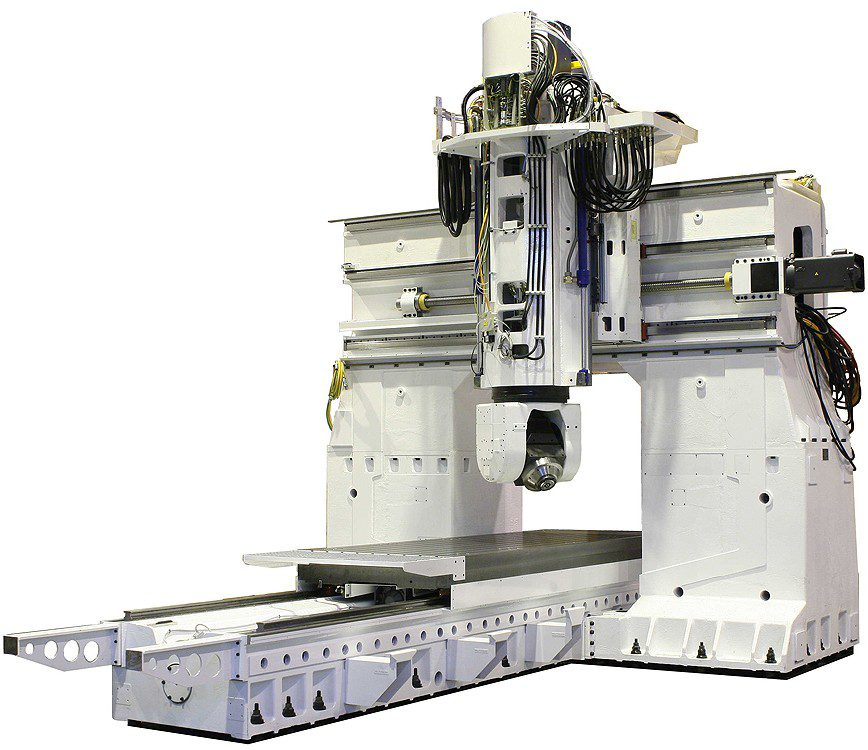

Gantry & Portal Milling Machines

Our gantry and portal milling machines offer precision and quality for large-scale operations. They are equipped with large CNC controls for easy program control and remote diagnostics. With features like high rigidity, automatic tool changer and vertical bridge mill, these machines are redefining the norms of large-scale machine transfer, installation and operations.

Gantry milling machines utilize a moving crossbeam that spans the workzone on dual side supports, providing strength and versatility. The spindle head travels on the gantry to position tools anywhere on the X, Y and Z axes, allowing for efficient 5-sided machining. Our large CNC gantry mills from top brands like Hexram and Huron give you the flexibility and accuracy to machine extremely tall, heavy parts.

Portal milling machines have a stationary spindle head mounted to robust twin columns, while the worktable travels along the Y-axis between them. This rigid construction bears heavy loads while minimizing vibration. The inverted vertical milling design provides superior chip management over the workpiece. Our portal mills from Hexram feature optional rotary tables for simultaneous 5-axis cutting suitable for aerospace components or impellers.

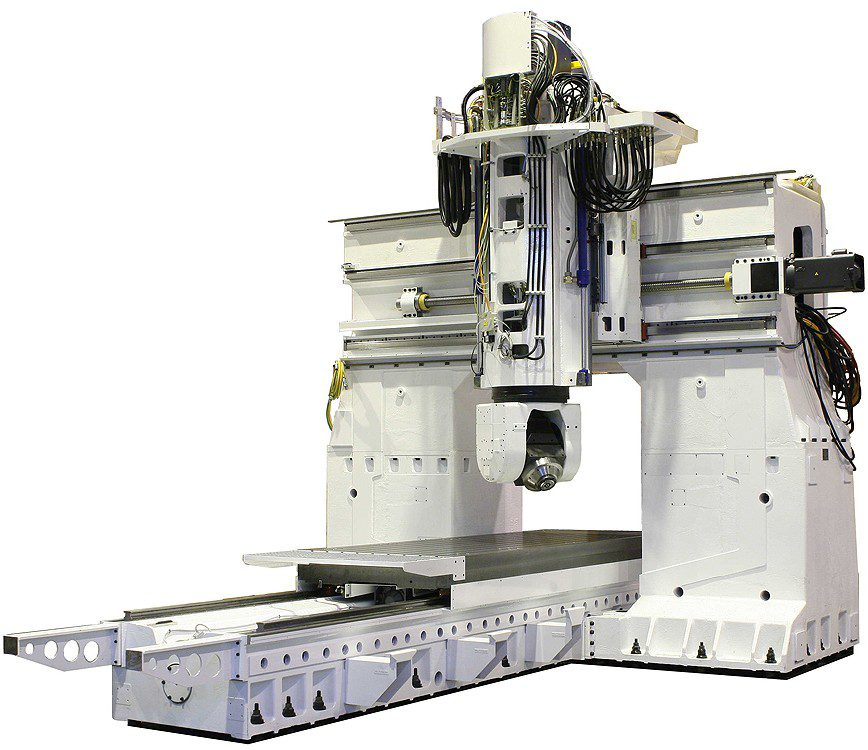

Horizontal Mills

Horizontal milling machines are perfect for tasks demanding high precision and power. They are equipped with a robust spindle unit and ball screws for perfect alignment and accuracy.

The automatic tool changer feature enhances the productivity of these machines while ensuring accuracy at all times. With a large working enclosure, horizontal mills can handle larger workpieces.

Multiprocess Machines

Multiprocess machines fuse various functions into one to deliver efficient and precise results. Equipped with an automatic pallet changer and automatic tool changer, they offer high productivity. The availability of spindle rebuild and spare parts repair services ensures the long-term reliability and durability of these machines.

For example, Mausa’s heavy-duty boring machines feature a movable column design ideal for highly productive large part machining. Their range covers dedicated solutions for wind turbine and hydroelectric components, with maximum productivity for the aerospace industry’s oversized parts. MTE offers a variety of multi-axis universal machining centers with rotary tables and infinitely positioning heads for precision machining complex components in a single setup.

5-Axis Traveling Column

Built for high rigidity and precision, our 5-axis traveling column machine can handle large-volume machining tasks efficiently. The high-speed spindle with variable speed control makes this machine more versatile. This machine comes with advanced features such as end-mill compatibility, OEM retrofit capability and remote diagnostics.

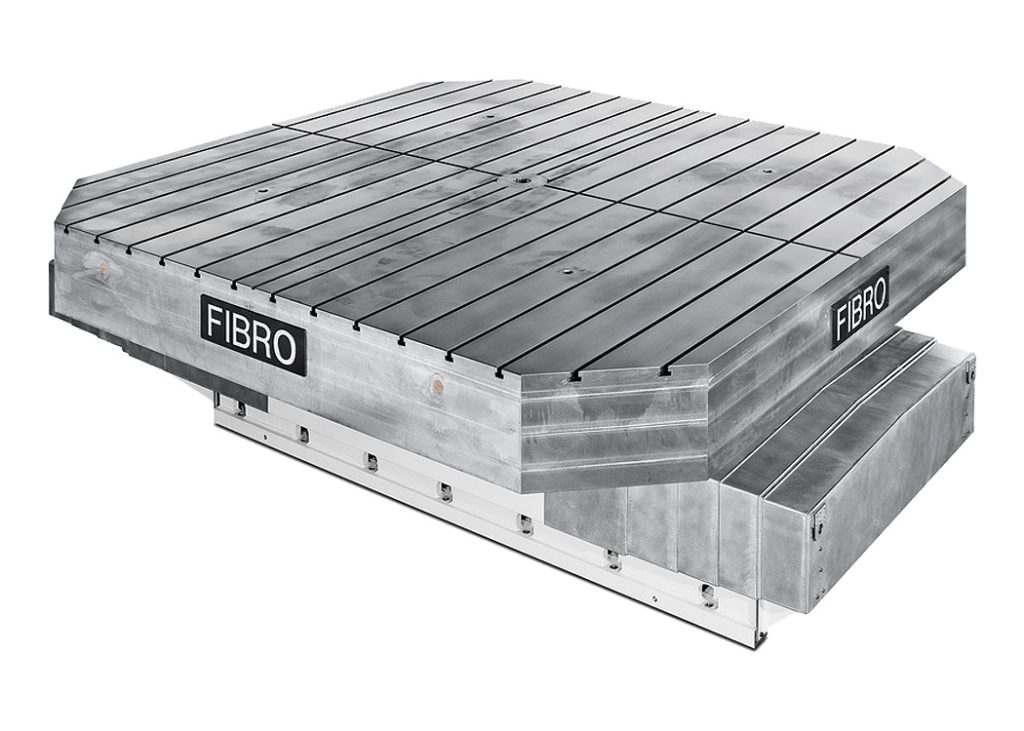

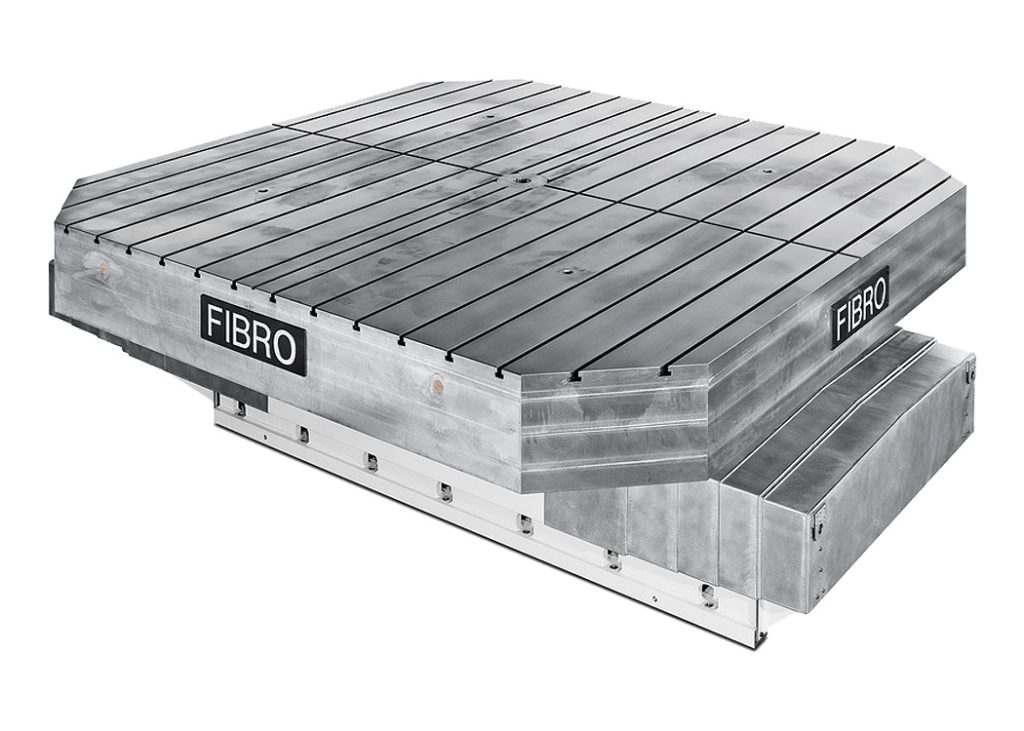

Rotary Tables

With high precision, efficiency and flexibility, our rotary tables add value to the CNC machining process. Built for longevity, these tables transform a 3-axis machining center into a 5-axis machine for complex machining tasks.

They feature superior indexing capabilities with advanced CNC control, which boosts productivity and reduces machining time.

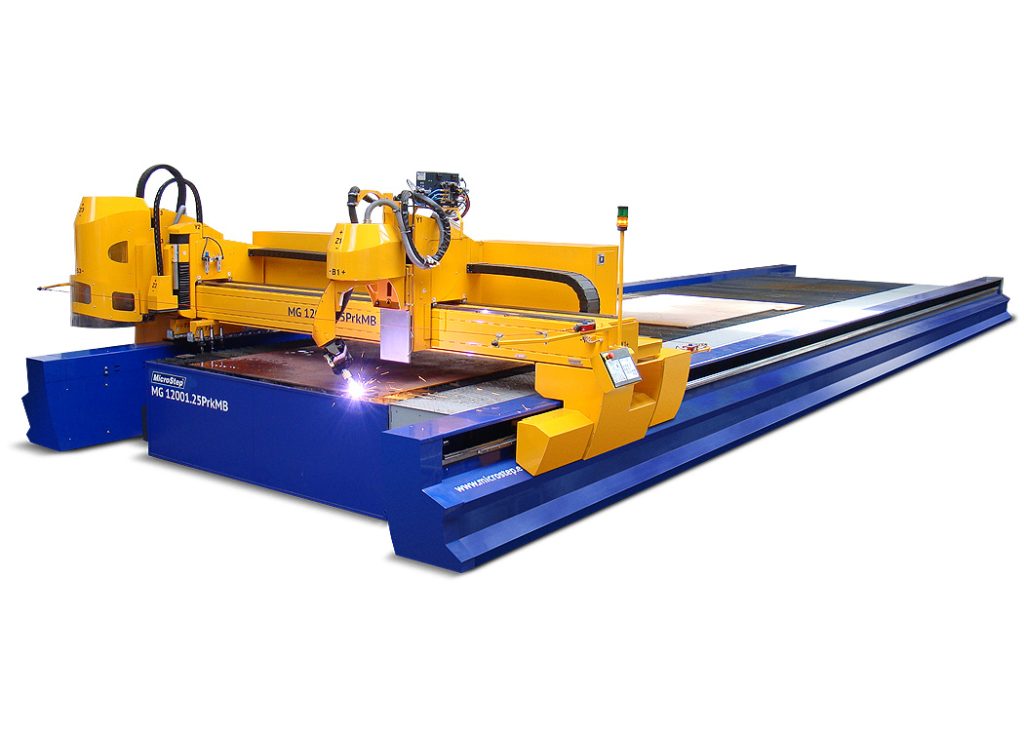

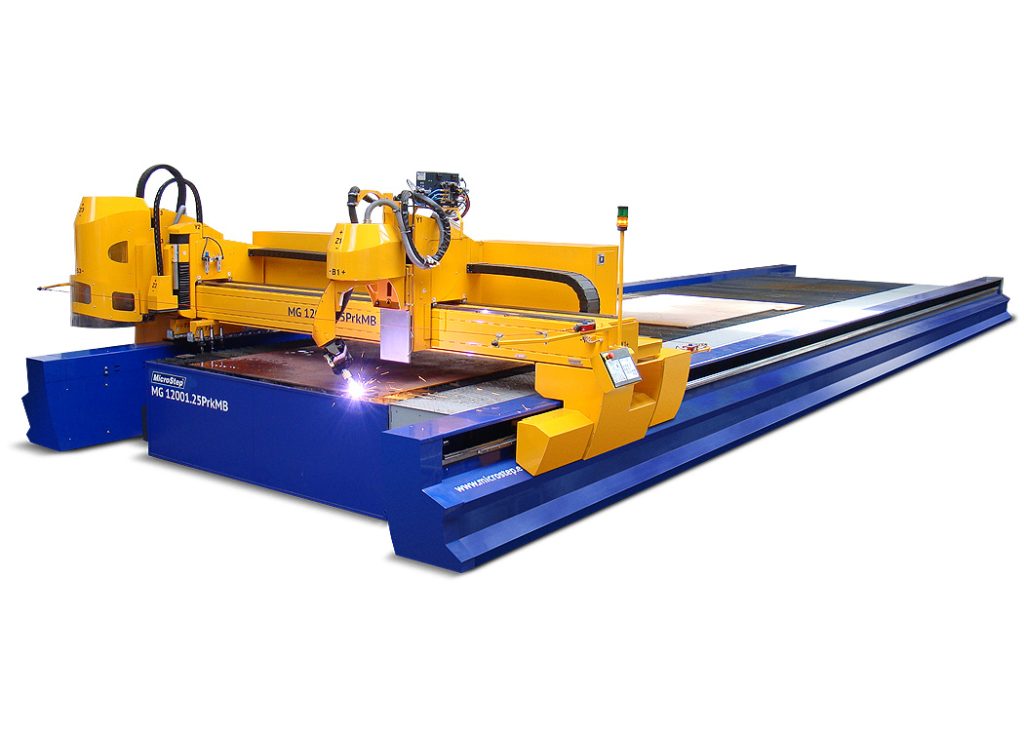

Plasma Machines & Oxyfuel Machines

Our range of plasma machines and oxyfuel machines are developed to deliver clean, precise and efficient cutting operations. They have a robust build and are equipped with advanced CNC control for easy operation. Armed with advanced plasma technology and oxyfuel-cutting capabilities, these machines can seamlessly handle thick materials and large workpieces.

We offer heavy-duty gantry style machines from MicroStep capable of automated bevel cutting, pipe profiling, drilling and part marking for unrivaled cutting versatility. With custom equipment like plasma rotators, oxyfuel triple torches and programmable Z-axis strokes, we can handle 3D shapes, domes and elbows.

Pipe & Profile Cutting Machines

Our pipe and profile cutting machines are designed to deliver accurate and efficient cutting of tubes and profiles. Thanks to their modern design, these cutting machines offer easy loading and unloading, rapid setup and accurate cutting.

The MicroStep line features dedicated machines for structural steel profiles, production of steel structures, tank and pipeline fabrication and power plant construction. With customized zones for cutting I-beams, rectangular tubes and pipes, our flexible platforms handle everything from weld prep to precision openings for multi-axis intersections.

Structural Beam Cutting Machines

Structural beam cutting machines are specialized tools for the effective, efficient and accurate cutting of structural beams. They are designed with large work enclosures, allowing for the handling of large beams.

With automated processes and remote diagnostics, these machines can deliver precise cuts consistently. This, coupled with reliable repair services, ensures their long-term operation.

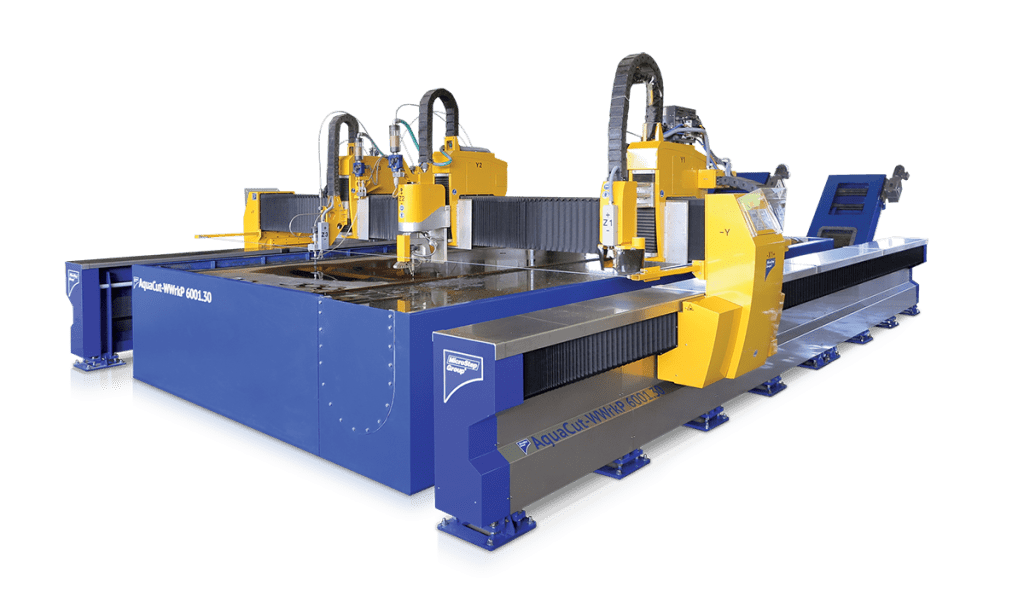

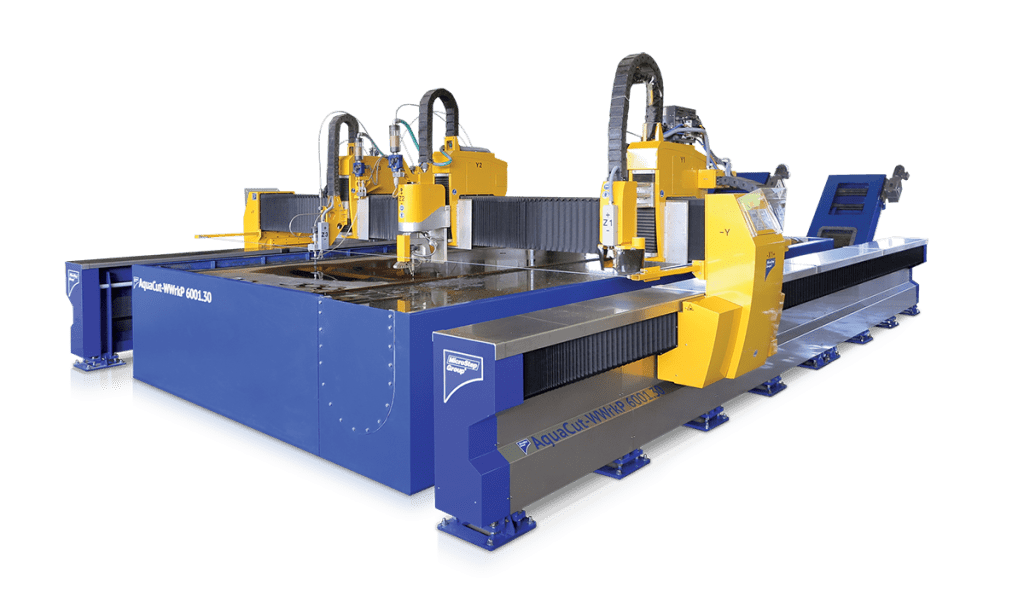

Waterjet Machines

Waterjet machines use high-pressure water jets to cut through materials. They provide precision, versatility and an eco-friendly machining process. These machines enable cuts through materials regardless of their hardness, making them suitable for a wide range of applications. They are particularly useful for materials that should not be subjected to intense heat or mechanical stress.

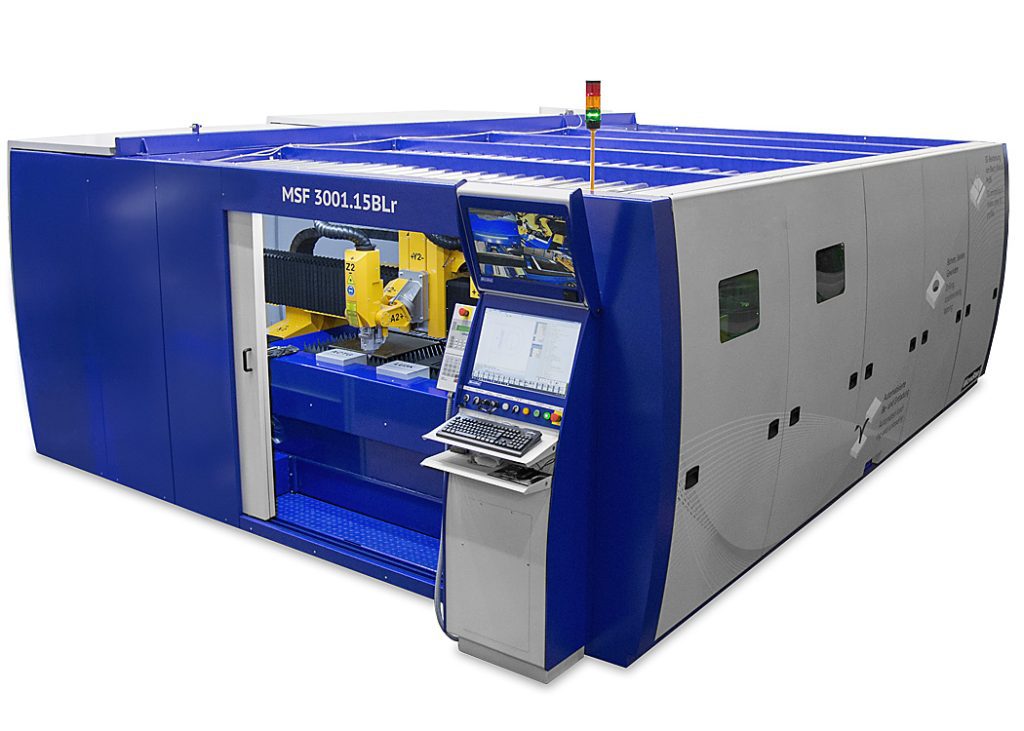

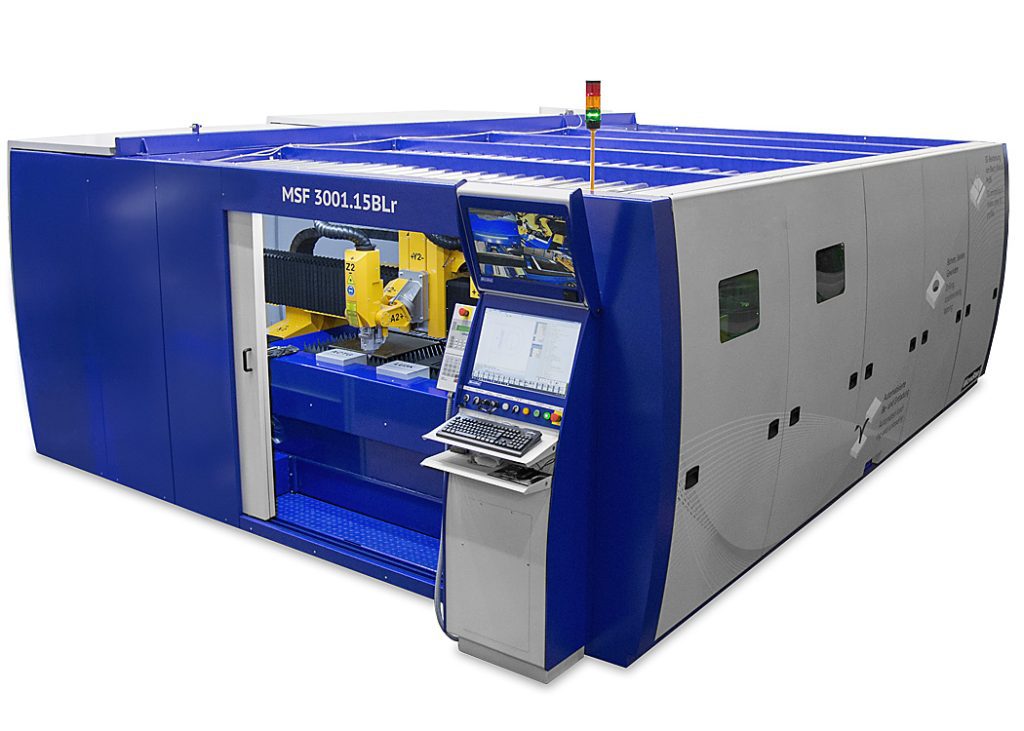

Laser Machines

Our laser machines are perfect for operations requiring high precision and accuracy. The machines generate extreme heat to melt and vaporize materials, resulting in clean and precise cuts. Our laser machines smoothly handle complex and intricate tasks.

The MicroStep line features laser machines designed for everything from high-speed cutting to the bevel cutting of massive steel structures over length. With single to multiple laser heads, these CNC machines achieve superior edge quality and positional accuracy for thick plate, pipe and profile workpieces. We also offer automated loading/unloading systems and buffer storage towers to enable round-the-clock production.

Press Brakes

Press brakes, built for bending sheet and plate material, are indispensable for metal fabricating tasks. With large work enclosures, our press brakes can handle large workpieces and deliver precise results.

Press brakes utilize tremendous force to transform flat sheet metal into precise angles and forms. As the punch presses down, the sheet metal is squeezed between it and the shaped die below causing the material to plastically bend along the predetermined form. With capacities up to thousands of tons, today’s large CNC press brakes employ hydraulic, servo electric or eccentric drive systems to supply the needed pressures for bending thick plates with tight tolerances.