Plasma Machines & Oxyfuel Machines

MicroStep DRM

DRM is a heavy-duty CNC cutting machine designed for a wide range of dome, sheet and pipe applications. Its robust gantry allows a vibration-free operation of heavy equipment such a automatic oxyfuel triple torches, a 120° rotator with a 1.5 m stroke of Z-axis for cutting of 3D shapes and other custom equipment.

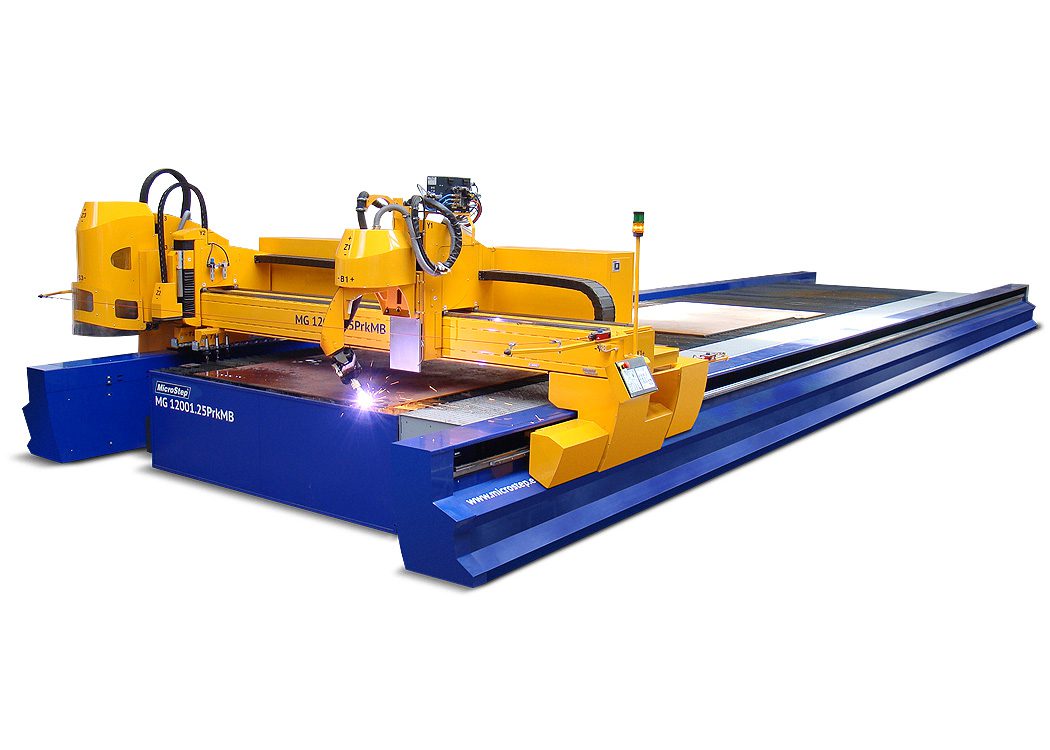

MicroStep CombiCut

This robust and high-precision CNC machine is designed especially for multiple-shift high-performance plasma and oxyfuel cutting. It allows cutting of steel up to 300 mm, bevel cutting with a pair of rotary oxyfuel triple torches or plasma rotators, simultaneous cutting with more than 10 torches, drilling up to Ø 40 mm, inkjet or micropercussion marking, pipe and dome processing.

MicroStep MasterCut

The application range of the entry version with rails in X direction dedicated to fully automated oxyfuel cutting or cutting with conventional plasma can be enhanced to a variety of high precision plasma cutting applications including pipe, profile or elbow cutting and marking.

MicroStep MasterCut Compact

MasterCut Compact is a dynamic, high precision CNC cutting machine suitable for a variety of plasma and oxyfuel cutting jobs. Thanks to its sophisticated design and high quality of components it smoothly provides latest features of plasma technology for a decent price – true contours, small holes, sharp corners and efficient operation.

MicroStep MSLoop

The application range of the entry version with rails in X direction dedicated to fully automated oxyfuel cutting or cutting with conventional plasma can be enhanced to a variety of high precision plasma cutting applications including pipe, profile or elbow cutting and marking.

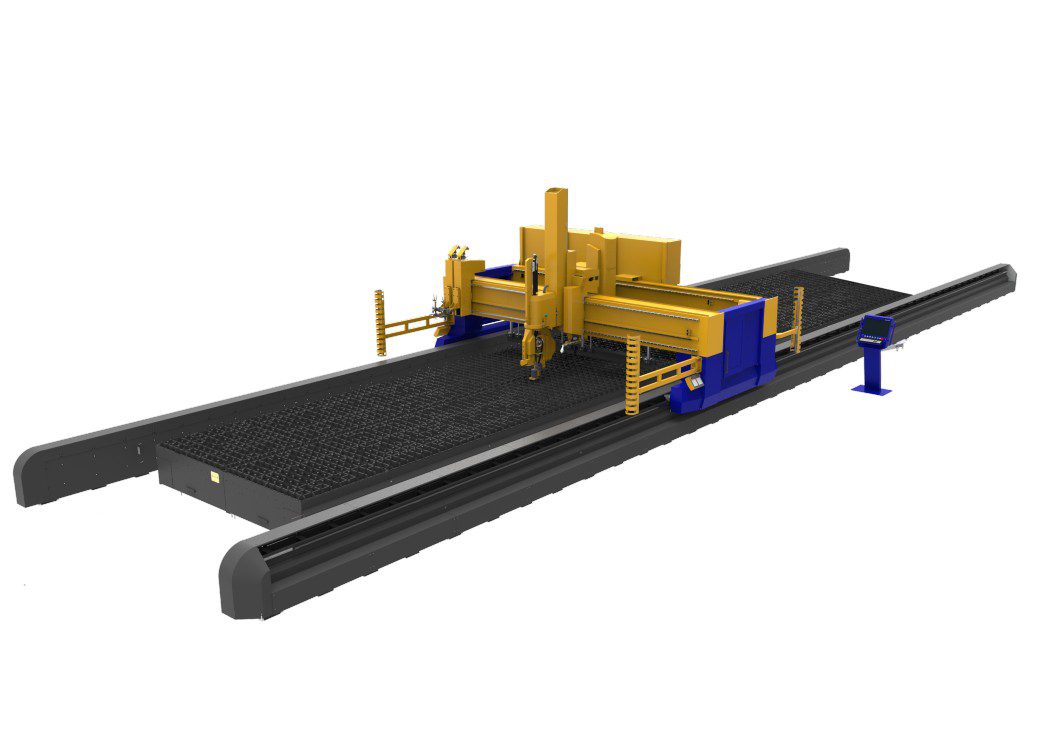

MicroStep DRM Max

DRM Max is a heavy-duty CNC cutting, drilling & milling machine with key applications in offshore, wind tower, heavy vessels, columns, reactors, and heavy-duty machinery segments. The machine has a dedicated drilling/milling area with an independent sub-gantry and two powerful retainers. The robust design enables drilling up to Ø 70 mm (2.75”) diameter and a variety of milling jobs such as large hole milling, face milling, pocket & slot milling, chamfer milling, thread milling or counter boring. Can also be equipped with other accessories to process plate, pipe, beam, and dome cutting applications.

What Are Plasma Machines?

Plasma cutting machines utilize a superheated, electrically ionized gas jet to cut through metal. This gas plasma beam is hot enough to instantly melt steel, stainless steel, copper, aluminum, and more. Plasma cutters deliver extremely precise cuts at rapid speeds unmatched by most other methods.

They are popular options for fabrication shops, machine shops, automotive restoration companies, and industrial manufacturers who require versatile and efficient metal cutting capabilities. As a leading provider of large-scale CNC machinery, United Precision Services offers premier plasma CNC tables from top brands for customers across industries.

Main Components of Plasma Machines

A standard plasma machine consists of several key components:

- Power Supply: This component converts single or three-phase line voltage into smooth, constant DC voltage — a necessity for maintaining the plasma arc throughout the cutting process.

- Gas Supply: This provides the compressed gas that flows through the torch to create the plasma jet. The gas supply system includes storage tanks and regulators to deliver a steady, controlled gas feed to the torch.

- Plasma Arc: This is where the actual plasma cutting process takes place. It is an electrically conductive gas column capable of melting metal at high temperatures.

- Torch: The torch is the tool that guides the plasma arc onto the material. Models come equipped with a uniquely designed torch for a clean cut.

- CNC Interface: The CNC interface is the control system for automated plasma cutters. It guides the movement of the torch according to programmed instructions.

How Does a CNC Plasma Machine and Oxyfuel Cutter Work?

CNC plasma cutting directs a plasma torch along a pre-programmed path to cut metal parts automatically. The CNC machine loads the cutting file and positions the metal workpiece precisely under the plasma torch. According to the code instructions, the superheated plasma jet slices through the material rapidly along the defined cut lines.

CNC oxyfuel systems also utilize programming to guide an automated cutting head. However, instead of electricity, oxyfuel cutters mix and ignite oxygen and fuel gases to generate an extremely hot flame. This high-temperature chemical reaction melts through the metal.

Plasma Machine Features and Specifications

The advancements in plasma cutting engineering have immensely improved the capabilities and functionality of these systems. Plasma machines, equipped with state-of-the-art features, have made cutting metals like stainless steel more efficient and precise. Let’s look at the specific features of modern CNC plasma cutting:

- Recommended Cutting Capacity: The recommended cutting capacity for plasma cutters is generally up to 2″, depending on the model and power source. This spectrum represents the ideal metal thickness these machines can cut at the highest speed without compromising the cut quality.

- Maximum Cutting Capability: The maximum cutting capability refers to the most substantial thickness that a plasma cutter can manage. Most systems are designed to handle upwards of 3″, with some heavy-duty models able to handle metals up to 6″ thick. However, the cutting speed decreases, and cut quality may vary on the upper end of this capability.

- Clean Cut: One of the significant advantages of plasma cutters is the efficient and clean cut they provide. With superior precision, plasma cutting machines like the MicroStep models we offer provide less wastage and a smoother surface on the cut piece.

Oxyfuel Machine Features and Specifications

Oxyfuel machines employ a different cutting process from plasma machines, utilizing oxygen and fuel gases (such as propane, natural gas, or acetylene). This gives them unique features and specifications:

- Cutting Speed: Oxyfuel cutting machines have a slower cutting speed compared to plasma cutting systems. This characteristic offers an advantage in situations where precision is essential over speed.

- Bevel and Straight Cutting: Oxyfuel machines have the added functionality of bevel cutting and straight cutting. This feature is particularly useful when dealing with projects requiring angled cuts.

- Cutting Width and Length: The cutting width and cutting length are substantial specifications for an oxyfuel machine. These dimensions dictate the maximum size of the metal that the machine can process. Regularly priced, oxyfuel machines, like the CNC router models, are adept at handling wider and lengthier metals.

Plasma and oxyfuel machines cater to different needs in the cutting industry. Our sales team can guide you through the technical aspects of each to ensure you get the machine tailored to your unique machining requirements.

* Indicates required entries.