Lazzati

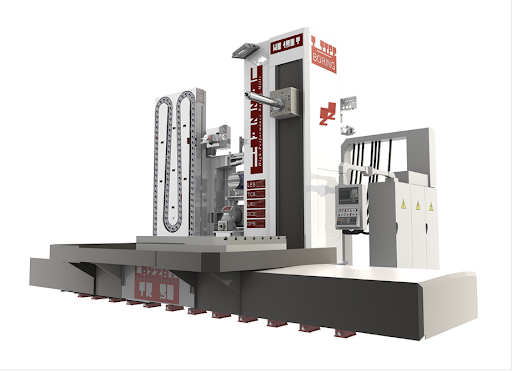

Lazzati horizontal boring mills are advanced and incredibly versatile manufacturing machines used to produce large, complex metal components with extreme precision. With their rugged build, superior power, and exceptional accuracy, these mills are a workhorse of modern manufacturing, used everywhere from aerospace and defense to energy and transportation.

Our Product Range

Lazzati Horizontal Boring Mills

Linea T-Type

X = 2.000-7.000 (Cross)

Y = 2.000-4.000 (Vertical)

Z = 1.500-3.000 (Columns/Transverse)

W = 900-1.600 (Spindle/RAM)

Linea Floor Type

X = 4.000-40.000 (Cross)

Y = 2.000-7.000 (Vertical)

Z = 1.000-2.000 (RAM)

W = 1.000-1.100 (Spindle)

What Are Horizontal Boring Mills?

Horizontal mills range in functionality and design, with various features that cater to specific industry needs. As their name suggests, these machines orient the cutting tool spindle in a horizontal orientation instead of a vertical one. The horizontal configuration also provides unencumbered access to all sides of a part for complex and detailed machining operations. This directly impacts the type of machining work that can be accomplished.

Horizontal Boring Mill Features & Specifications

United Precision Service’s horizontal boring mill is equipped with an advanced high-speed guiding system for efficient workpiece processing. They stand out due to their cutting-edge design and technology, exceptionally high performance and durability. They also ensure safe and user-friendly operation, upholding the finest standards in function and safety. Here are the key features and benefits.

Efficiency and Power

Large main spindles, beefy axis drives, and advanced CNC controls equip our horizontal mills to make short work of big metal-removal jobs. Generous horsepower ratings cut through steel with ease. Geared headstocks churn out high levels of torque for difficult machining procedures, while programmable coolant delivery systems enhance chip evacuation and temperature control.

Versatility and Flexibility

Job shops and manufacturers demand equipment flexible enough to handle whatever walks through the door. Our horizontal mills are engineered for diverse professional manufacturing environments with variable application needs. Their flexible capabilities are suited for adapting to new jobs and workpieces that walk through the door.

Precise & Detail-Oriented Operations

Surpassing precision standards is crucial when working in strict aerospace, medical, and nuclear applications. Our horizontal mills meet these expectations with exacting accuracy

Longevity and Durability

Horizontal machining center purchase decisions aren’t made lightly, so maximum uptime and longevity are pivotal. These machines are engineered for rugged durability.

Benefits of Using Our Machines

Enhanced Precision and Versatility

Durability and Endurance

Improved Efficiency and Cost-Savings