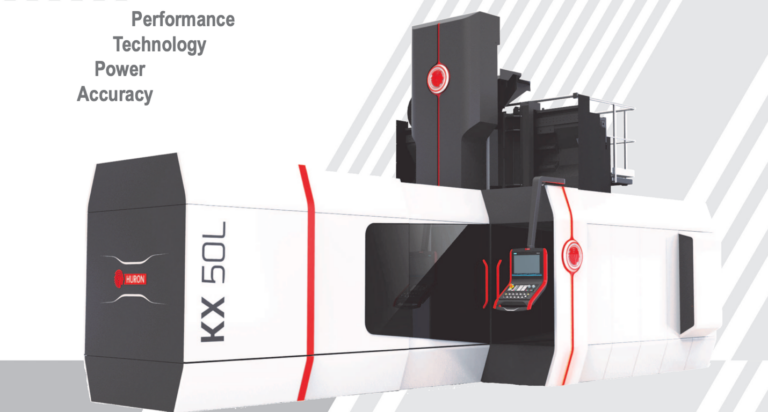

HURON

Huron’s 5-axis Gantry Milling center allows machining operations on 5-axis and 5-sides to be carried out in one setup from roughing to finishing. It is particularly suitable for large complex parts intended for machining molds, dies, stamping tools, models, and precision parts.

Our Product Range

Huron Gantry Milling Machines

kx large

X = 2.000-3.300

(Longitudinal)

Y = 1.700-2.300 (Cross)

Z = 800-1.000 (Vertical)

KX Five

X = 780-900

(Longitudinal)

Y = 700-900 (Cross)

Z = 500 (Vertical)

MX

X = 750-2.300

(Longitudinal)

Y = 700–2.300 (Cross)

Z = 500-1.250 (Vertical)

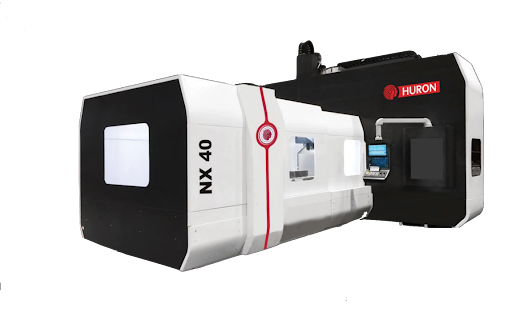

NX

X = 2.200-4.200

(Longitudinal)

Y = 1.500-2.700 (Cross)

Z = 800-1.000 (Vertical)

What Are Gantry milling Machines?

Gantry mills are large industrial machines that have a bridge-shaped moving horizontal arm, called a gantry, to which the milling head and spindle are attached. They are often used for large-scale milling projects where an overhead crane feeds large workpieces into the cutter on the gantry, allowing knee-less horizontal milling on a grand scale. Gantry mills can also be equipped with automatic tool changers, rotary tables and multiple axes, allowing them to perform complex milling similar to larger, precise vertical mills, but with the capability of handling bigger parts weighing tons.

Gantry Machine Features & Specifications

United Precision’s gantry machines offer a wealth of advantages to clients across multiple industries. Our top-of-the-line machines promise superior accuracy, speed and cost efficiency, as well as a range of customizable tooling options.

Superior accuracy and Precision

Our gantry and portal mills are designed for unparalleled cutting accuracy. With advanced vertical turning machines and vertical machining centers, you can expect premium performance with high precision and repeatability.

Time and cost efficiency

Efficiency is a critical factor in any production line, and our portal mills are engineered for optimization. By marrying high-quality performance with durability, United Precision’s equipment delivers results faster and at a fraction of the cost

Customizable tooling options

We recognize that adaptability is key in a fast-paced manufacturing environment, which is why we offer a wide variety of customizable tooling options. From specialized spindle rebuilds to OEM retrofit services, our solutions are designed to meet your unique needs and challenges.

Benefits of Using Our Machines

Enhanced Precision and Versatility

Durability and Endurance

Improved Efficiency and Cost-Savings